Stand Post Type Water Monitor (IS 8442)

- Size: 63 mm (2.5") with 1750 lpm at 7 bar

- Size: 75 mm (3") with 2580 lpm at 7 bar

- Size: 100 mm (4") with 3500 lpm at 7 bar

- Hot dip galvanized carbon steel waterway

- Maximum service pressure 12 bar (175 psi)

- Monitor with fixed flow solid bore nozzle available in Al., SS, GM.

- Bronze swivel joint with double row of stainless steel ball bearing

- Vertical & horizontal movement by handle and manual lock

- 360° continuous horizontal rotation & +90°, -45° vertical elevation

Water Cum Foam Monitor

- Size: 63 mm (2.5") with 1750 lpm at 7 bar

- Size: 75 mm (3") with 2580 lpm at 7 bar

- Size: 100 mm (4") with 3500 lpm at 7 bar

- Hot dip galvanized carbon steel waterway

- Maximum service pressure 12 bar (175 psi)

- Monitor with fixed flow solid bore nozzle available in Al., SS, GM.

- Bronze swivel joint with double row of stainless steel ball bearing

- Vertical & horizontal movement by handle and manual lock

- 360° continuous horizontal rotation & +90°, -45° vertical elevation

Stand Post Type Water Monitor ( Spray And Jet )

- Size: 63 mm (2.5") with 1750 lpm at 7 bar

- Size: 75 mm (3") with 2580 lpm at 7 bar

- Size: 100 mm (4") with 3500 lpm at 7 bar

- Hot dip galvanized carbon steel waterway

- Maximum service pressure 12 bar (175 psi)

- Monitor with fitted foam flow nozzle made out of Aluminium.

- Bronze swivel joint with double row of stainless steel ball bearing

- Vertical & horizontal movement by handle and manual lock

- 360° continuous horizontal rotation & +90°, -45° vertical elevation

Stand Post Type Water Monitor (Spray And Jet)

- Hot-dip galvanized carbon steel waterway

- 75 mm (3") waterway with flanged inlet of 80, 100 or 150 mm (3", 4" or 6") & outlet threaded to 3" BSP male

- Vertical and horizontal movement by handle and manual lock

- Easy deployment by one person

- Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

- Maximum operating pressure 12 bar (175 psi)

- 360° continuous horizontal rotation & +90°, -45° vertical elevation

- With master steam nozzle having flow of 3000 LPM (800 GPM)

Stand Post Type Water Monitor (Spray And Jet)

- Hot-dip galvanized carbon steel waterway

- Vertical and horizontal movement by handle and manual lock

- 100 mm (4") water way with 100 or 150 mm (4" or 6") flanged inlet & 4" BSP outlet

- Bronze swivel joint with double row of stainless steel ball bearing and grease fittings

- Maximum operating pressure 12 bar (175 psi)

- 360° continuous horizontal rotation and +90°, -45° vertical elevation

- Flow up to 4700 lpm (1250 gpm) at 6.8 bar (100 psi) friction loss less than 10 psi

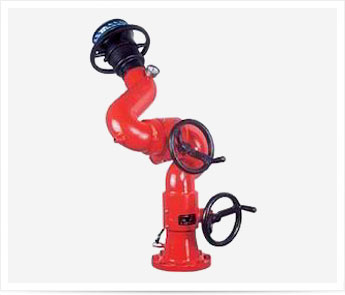

Stand Post Type Water Monitor Geared ( Spray And Jet )

- Hot dip galvanized carbon steel waterway and bronze swivel joint

- Size 80, 100 or 150 mm (3", 4" or 6") flanged inlet with 3" BSP male threaded outlet

- Double row of stainless steel ball bearing with grease fittings

- Liquid filled pressure gauge (optional)

- Fully enclosed worm gear for horizontal and vertical movement

- 360° continuous horizontal rotation and +90°, -45° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Flow up to 3000 lpm (800 gpm) friction loss less than 10 psi

- Red polyurethane finish

Stand Post Type Water Monitor Geared ( Stream Nozzle )

- Hot dip galvanized Carbon steel waterway and Bronze swivel join

- Size 100 mm (4") with 100 or 150 mm (4" or 6") flanged inlet and 4" BSP male outlet

- Double row of Stainless Steel ball bearing with grease fittings

- Liquid filled pressure gauge (optional)

- Fully enclosed worm gear for horizontal and vertical movement

- 360° continuous horizontal rotation and +90°, -45° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Flow up to 4700 lpm (1250 gpm) friction loss less than 10 psi

- With master stream nozzle and solid bore nozzle

- Red polyurethane finish

Stand Post Type High Volume Water Monitor Geared (Stream Nozzle)

- Low profile design

- Hot dip galvanized carbon steel waterway

- 80, 100 or 150 mm (3", 4" or 6") flanged inlet with 3" BSP male threaded outlet

- Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

- Fully enclosed worm gear for horizontal and vertical movement of monitor

- 360° continuous horizontal rotation and +90°, -65° vertical elevation

- Maximum operating pressure to 12 bar (175 psi)

- Liquid filled pressure gauge

- Flow up to 3000 lpm (800 gpm) friction loss less than 10 psi

- Red polyurethane finish

Stand Post Type High Volume Water Monitor Geared (Stream Nozzle)

- Low profile design

- Hot dip galvanized carbon steel waterway

- Size 100 mm (4")

- 100 or 150 mm (4" or 6") flanged inlet with 4" BSP male threaded outlet

- Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

- Fully enclosed worm gear for horizontal and vertical movement of monitor

- 360° continuous horizontal rotation & +90°, -65° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Liquid filled pressure gauge

- Flow up to 4700 lpm (1250 gpm) friction loss less than 10 psi

- Red polyurethane finish

Stand Post Type High Volume Water Monitor Geared (Stream Nozzle)

- Low profile design- Hot dip galvanized Carbon steel waterway

- Bronze swivel joint with double row of stainless steel ball bearing

- 150 mm (6") flanged inlet and outlet

- Fully enclosed worm gear

- Maximum service pressure 12 bar (175 psi)

- 360° continuous horizontal rotation and +90°, -65° vertical elevation

- Liquid filled pressure gauge

- Single lifting hook

- Flow up to 12500 lpm (3300 gpm)

- Red polyurethane finish

- 60 master stream Nozzle with flow up to 2200 gpm

Stand Post Type High Volume Foam Monitor (Aqua Foam Nozzle)

- Low profile design

- Stainless steel waterway

- 100 or 150 mm (4" or 6") flanged inlet with 4" BSP male threaded outlet

- Fully enclosed worm gear for horizontal and vertical movement

- 360° continuous horizontal rotation and +90°, -65° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Liquid filled pressure gauge

- Variable flow with nozzle model H4V (500/750/1000GPM)

- Fixed flow with nozzle model H4 (500/750/1000GPM)

Stand Post Type High Volume Water Monitor Geared (Stream Nozzle)

- Cast Bronze Construction

- 360° continuous horizontal rotation and +90° & -45° vertical elevation or optional +85° & -0°/-15°/-30° vertical elevation

- Double Row of SS ball bearing & grease fittings

- Max operating pressure 12 bar (175 psi)

- Flow up to 1000 GPM (3800 LPM)

- Vertical and horizontal movement by handle and manual lock

Stand Post Type High Volume Water Monitor Geared (Stream Nozzle)

- Low profile design

- Cast bronze construction

- 80 or 100 mm (3" or 4") flanged inlet and 3" BSP male threaded outlet

- Hand wheel driven worm gear operated for vertical movement and manual lock with handle for horizontal movement

- Liquid filled pressure gauge

- 360° continuous horizontal rotation and +90°, -65° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Flow up to 3800 lpm (1000 gpm) at 6.8 bar (100 psi)

Stand Post Type High Volume Foam Monitor Geared (Aqua Foam Nozzle)

- Low profile design

- Cast bronze construction

- 80 or 100 mm (3" or 4") flanged inlet and 3" BSP male threaded outlet

- Hand wheel driven worm gear operated for vertical and horizontal movement

- Fully enclosed worm gear for horizontal and vertical movement of monitor

- Liquid filled pressure gauge

- 360° continuous horizontal rotation and +90°, -65° vertical elevation

- Maximum operating pressure 12 bar (175 psi)

- Flow up to 3800 lpm (1000 gpm) at 6.8 bar (100 psi)

- Red polyurethane finish

Stand Post Type High Volume Foam Monitor Geared (Aqua Foam Nozzle)

- Cast bronze construction

- Fully enclosed gear

- Liquid filled pressure gauge

- Double row of Stainless Steel ball bearing with grease fittings

- Maximum operating pressure 12 bar (175 psi)

- 115 mm waterway with 100 or 150 mm (4" or 6") flanged inlet and 4" BSP male threaded outlet

- 360° continuous horizontal rotation, +90°, -45° vertical elevation

- Red polyurethane finish

- Flow up to 7575 lpm (2000 gpm)

Stand Post Type High Volume Foam Monitor Geared (Aqua Foam Nozzle)

- Cast bronze construction

- Fully enclosed gear

- Liquid filled pressure gauge

- Double row of Stainless Steel ball bearing with grease fittings

- Maximum operating pressure 12 bar (175 psi)

- 115 mm waterway with 100 or 150 mm (4" or 6") flanged inlet and 4" BSP male threaded outlet

- 360° continuous horizontal rotation, +90°, -45° vertical elevation

- Red polyurethane finish

- Flow up to 7575 lpm (2000 gpm)

Oscilating Monitor

- Cast Bronze Construction

- 0 to 120° Oscillating Angle adjustable in 6 steps anywhere within 360°

- Water Driven wheel drives the oscillating mechanism

- No external wiring or hydraulic control required

- Double Row of SS ball bearing & grease fittings

- Max operating pressure 12 bar (175 psi)

- Flow up to 800 GPM ( 3000 LPM)

Water Cum Foam Monitor Mounted On Trolley Trailer

Storage tank trailers of 500-1000 ltr. capacity tank with choice of only foam barrel or water cum foam monitors (dual barrel) is available for high pressure water/foam application for long range requirement in certain areas. Where fixed hydrant system is far from the area where chances of fire occurs or where there is no enough space to run foam tender.

Specification : Indigenously designed as per customers specification constructed in M.S./ SS or as per design. Monitor sizes available in 63, 75 and 100 mm dia

Tank : Fully welded tank with internally Coats of epoxy paints coated to suit any type of foam in order to avoid corrosion & externally painted with 2 coats of red oxide Primer & 2 coats of synthetic enamel red paint (Also available in S.S.Construction)

Trailer * : Chassis welded rolled steel channel Construction, equipped with 2/4 tires with a front castor wheel & 4 jacks for resisting jet reaction force during fire fighting application

Trolley : Frame made of channel equipped with 2/4 trolley wheels of 10"/12" dia size with a front castor wheel & four stoppers for resisting jet reaction force during fire fighting application.

Lighting * : Reflective lights & break lights provided with wire mesh protection guards over glasses (only in trailer Models)

Trolley Mounted Water Cum Foam Monitor

This trolley/trailer mounted monitor models gives excellent mobility & stability allowing deployment on industrial & petrochemical sites which cannot be achieved with larger trailers and are very easy for one Man operation

Specification

Monitor : Any stand post type monitor of size 63mm to 100 mm can be fixed upon this Trolley/

Nozzle : Any type of nozzle can be fixed up with the monitor & same can be used for firefighting purpose.

Tires : Scooter tires

Iinlets : 2 to 5 nos. with built in spring loaded check valve inside male instantaneous coupling provided.

Recommendation : Use long range aqua foam type nozzles with monitor for long range application.

Optional Accessories : a) Dual racks for storing hoses b) Locker for nozzles c) Foam tank up to 200 ltrs.

Water Cum Foam Monitor

Standpipes for Fire Brigade use available with Aluminum / copper/ G.I. provided with Instantaneous/ threaded Inlet and Outlets.

Material of Construction : Aluminum / Copper/ G.I. Pipe. Gunmetal/ Al. alloy Inlet/ Outlet.

Inlet : Female Instantaneous/ round thread.

Outlet : Swivel head/ female Instantaneous.

Sizes : 2½â€, 3â€, 4â€

Item Description : Fire Hydrant Stand Pipe Single outlet, having 63mm Female Round Thread / Female Inst. Inlet & 63mm Female Inst. Outlet used for Underground Fire Hydrant Valve

Stand Posts

Stand posts for mounting of Hydrants/ monitors in Firewater systems. Welded Construction.

Material of Construction : M.S. Pipe to IS:1239 class C, M.S. Flanges as per IS:2603

Hydraulic Pressure tested to : 30 Kg/cm2

Outlet : Flanged.

Sizes : 21/2â€, 3", 4", 6"

Item Description : MS Single Stand Post Flanged Inlet & outlet for mounting Fire Hydrant Valve

Item Description : MS Stand Post 75 / 100mm NB flanged Inlet & 1 / 2 nos. 80mm NB flanged outlet for mounting 2 nos. single outlet Fire Hydrant Valve